Electrical Infrared Thermal Inspection

What is an Infrared Thermal Inspection?

Infrared is a non-destructive, predictive maintenance tool which is capable of detecting anomalies, based on the load conditions of the equipment creating a "snap-shot-in-time" of your equipment's thermal image.

The goal of infrared (thermal) inspection is to survey the designated electrical equipment to pinpoint defective components and elevated temperatures in your power system.

Why should I have an Infrared Inspection performed?

If unfound or untreated, thermal "hot spots" can cause potential explosions, fire, or other electrical service interruption threats. Thermal hot spots are generally caused by overloaded or unbalanced electrical circuits, broken equipment, or loose connections.

These conditions are often overlooked during routine facility evaluations. They can result in the release of heat that will be visible only through infrared themography detection services.

Benefits:

A typical electrical infrared survey can, on average, save $10,000 to $20,000 depending on the number and category of anomalies found. In addition to direct financial savings, valuable time is saved by incorporating an annual infrared inspection into your electrical maintenance program. This can cut down on maintenance time, prevent costly replacements, and help eliminate unforeseen outages and downtime.

- Reduces electrical fire hazards

- Maintain the integrity of your facility's electrical system

- Detect faulty connections and overloaded circuits

- Provide uninterrupted power to clients/tenants/employees

- Provide a "snap-shot-in-time" of the condition of your equipment

- Preventative or predictive maintenance programs can save money by reducing:

- pre-mature equipment failure

- emergency overtime

- loss of revenue due to downtime

- overnight shipment of replacement parts

- insurance premiums (many insurance companies give discounts for performing regular infrared inspections)

Types of Electrical Equipment:

During the electrical infrared inspection we will generally inspect the following equipment, but we can provide inspection and imaging on any electrical or mechanical components according to your specifications.

- Switch Gears

- Transformers

- Service Disconnects

- Transfer Switches

- Motors / Pumps / Bearings

- Bus Runs

- Breaker Panels

- Motor Control Centers

- Starters

- UPS Equipment

- Chillers and Roof Top HVAC Equipment

- VFDs

- Lighting / Heating Contactors

Deliverables:

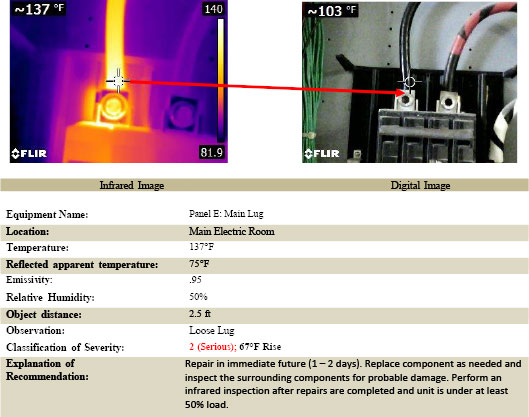

Our electrical infrared thermal reports are concise and to-the-point. We make anomaly location easy to determine so you can repair. Our report will provide a detailed and easy-to-read summary of:

- A complete list of the equipment inspected

- Written narrative of the survey

- A separate report form for every anomaly detected

Each report form for every anomaly/problem will include:

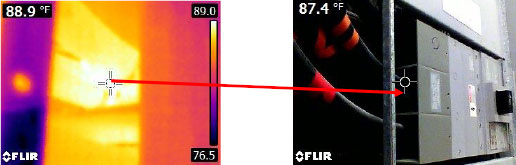

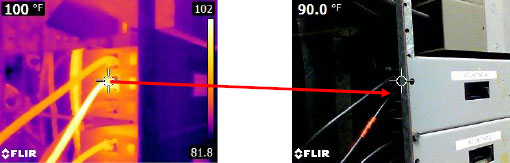

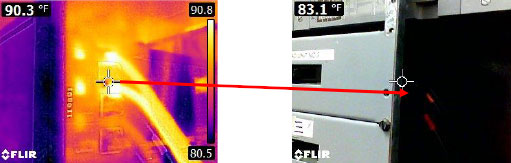

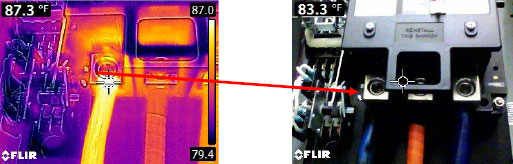

- Digital visible light photograph and color thermogram (infrared) picture

- Severity category of the problem to help you respond appropriately

- Physical location of the problem

- Problem area temperatures

- Likely cause of problem and Recommendations